Dust control and wetblasting –

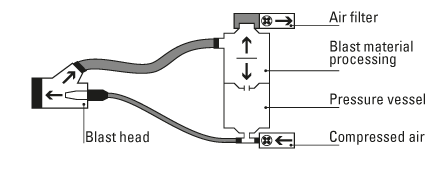

Clemco dust control systems with closed-circuit can be used to blast virtually anywhere. No elaborate containment or housing is needed. A closed-circuit blast system emits no abrasive particulate or dust and consumes a minimum amount of energy while maintaining the blast stream in a contained, safe pattern.

Dust-controlled blasting –

The closed-circuit and dust control systems from Clemco enables flexible blasting in many different outdoor and indoor locations, with minimal dust escape. Dust control equipment offers a closed-loop system that delivers abrasive to the surface while simultaneously recovering and reclaiming it and preventing dust egress. Different blast heads can be used to conform to different shapes and surface patterns, all while keeping the surrounding environment free of dust pollution.

- Environmentally protective closed loop system

- Cost savings through media reclamation

- No dust problems

- Simple operation

- Robust, reliable, durable systems

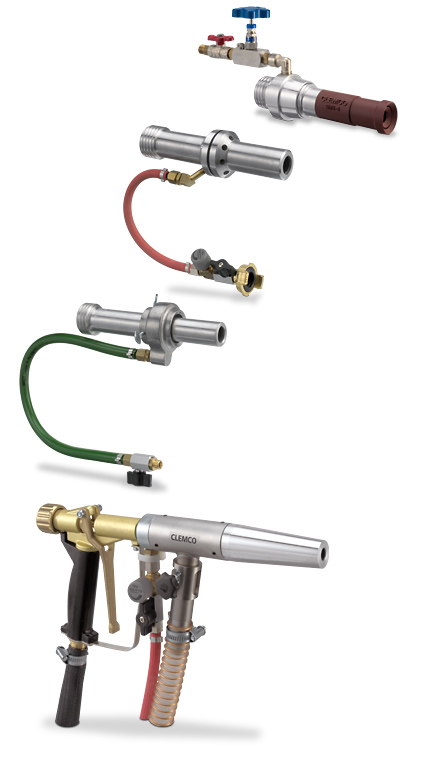

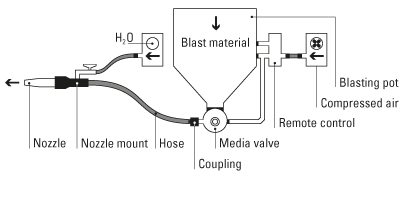

Closed-circuit system components

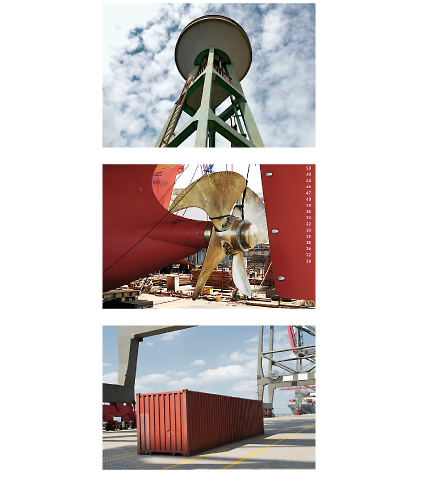

Wide range of applications

- Repair work in clean environments

- For sensitive surfaces

- Light to medium corrosion